What is Delta T in Air Source Heat Pump?

Today, much of the discussion about heat pumps focuses on temperature. We briefly discussed heat pumps vs. gas boilers in our blog, and again in this blog about high temperature heat pumps.

We mentioned flow/return temperature before, but didn’t discuss it in detail. In this blog post, we’ll look at what flow/return temperature is and what factors affect it.

What is temperature delta?

The temperature difference, also known as Delta T, DT, flow/return, is an extremely important aspect of heat pump performance. It is the difference between the temperature at the heat pump output and the temperature returning from the heating system.

While the temperature at the heat pump output is important, the temperature difference is perhaps even more important. The greater the temperature difference, the more efficient the heat delivery system.

Why is the temperature difference important?

Imagine a transportation company sends out a truck full of produce. If it comes back with only half of the cargo, you wouldn’t consider it a very efficient trip.

The same is true with temperature difference. An efficient system should return water that is significantly cooler than when it left the heat pump. The benefits of this are:

* You can use smaller pipes to move the same kilowatt-hour of heat

* Pumping costs will be lower due to lower water volumes

* Heat losses in return pipes will be lower

* Heat transfer within the building will be more efficient

However, the size of the temperature differential does not increase the benefits linearly. Extremely high temperature differentials will present practical challenges similar to those of the old steam system. The job of the system designer is to achieve the right balance so that the system works as efficiently as possible, resulting in the best carbon reduction and cost-effectiveness for the required level of heating.

What affects the temperature differential

There is a misconception that heat pumps must have a low temperature differential. This is incorrect.

You may see lower temperature differential values in the datasheets and promotional materials published by some heat pump manufacturers - we have seen designs based on 5 or 10 degree Celsius temperature differential values. However, these values are only correct if the manufacturer is using synthetic refrigerants. Using natural refrigerants, systems can be designed with much larger temperature differential values. Heat pumps using R744 (CO2) or R290 (propane) will also perform well with much higher temperature differential values.

We’ve written before about why we use CO2 in our heat pumps at Clade. CO2 is most efficient at a temperature differential of 30 or 40 degrees Celsius. This temperature differential is ideal for many heating applications as it delivers the required temperature while maximizing overall system efficiency.

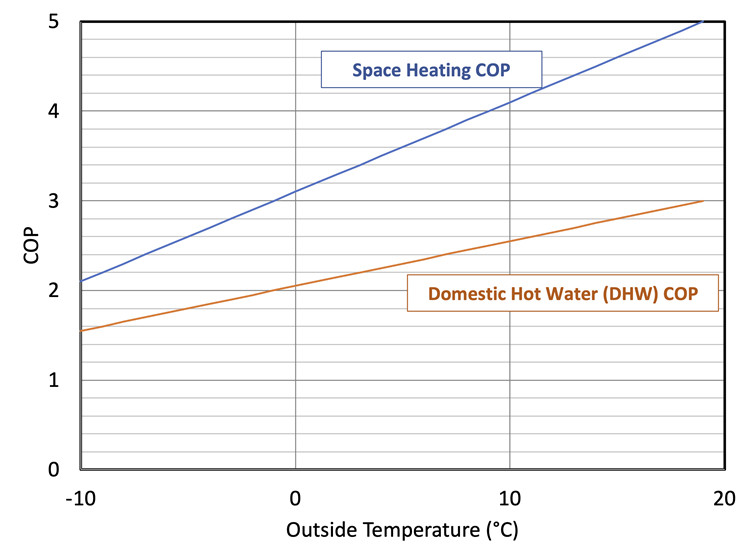

Below is an illustration of the relative COPs between CO2 and synthetic refrigerants. You can see that a larger delta T yields the highest COP at useful flow temperatures.

The thermodynamic properties of CO2 allow it to achieve high temperature heat transfer and low return temperatures. In addition to CO2’s efficiency advantages, it’s also worth remembering that CO2 is not subject to the HFC phase-out and therefore will not become prohibitively expensive in the coming years. It also will not catch fire, explode or leave permanent chemicals in our precious environment.

Conclusion

There are a few common misconceptions about heat pump technology, one of which is the belief that heat pumps necessarily have low temperature differentials.

We hope we’ve shown here that this is not the case – low DT is simply a consequence of the synthetic refrigerants that some heat pump manufacturers have chosen.

At Leomon, we use CO2 in our commercial heat pumps, which enables us to design and install extremely efficient systems that maintain higher temperature differentials, provide the required heat, and achieve higher total cost of ownership efficiencies than other systems. If you would like to discuss how we can help you develop a new system, please contact us.